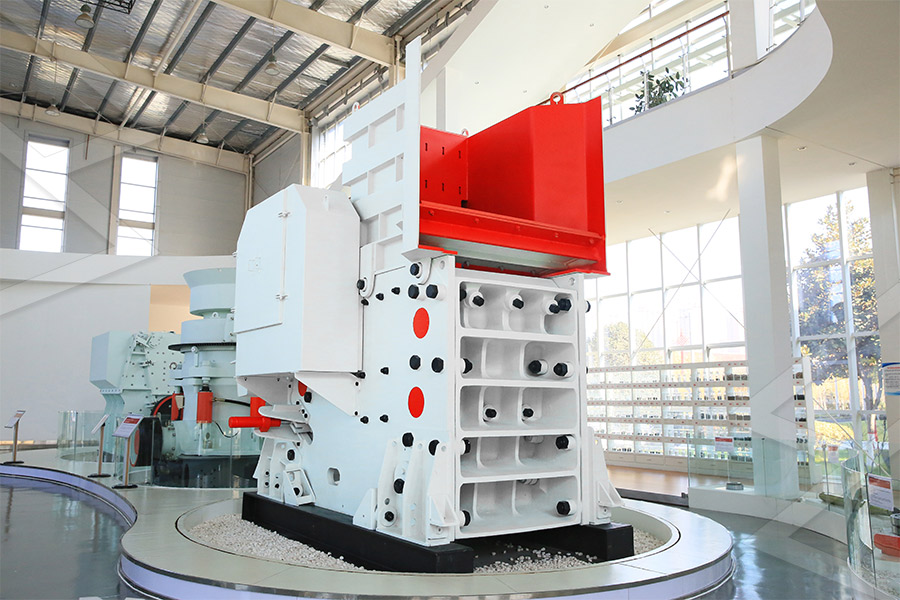

Simple And Easy Installation Good Function Roll Crusher

.jpg)

Electrical Roll Crusher simple and easy operation IKN

2023年5月31日 Operation is proven in coolers with capacities of up to 13,000 t/d The IKN Roll Crusher can be installed at the cooler discharge end or as a midcooler crusher for intermediate crushing Water cooling the crusher shafts is an option for hot operation, when installed in the 2022年11月6日 As roll crusher / roller crusher manufacturer , we will introduce its operation manual: 1how to install roller crusher 2how to test roll crusher 3how to opreate roller crusher 4maintenance of roller crusher 5how to Roll Roller crusher operation manual install 2021年9月18日 FOTE ROLL CRUSHER 04 APPLICATIONS OF ROLL CRUSHER This improved roll crusher with mightiness and high efficiency is developed by Fote’s senior Onestop Turnkey ROLL CRUSHER FTM Machinery2021年5月10日 In this article, we will introduce the complete installation guide of roll crusher including test running We had shared about the installation method of jaw crusher, hammer The Complete Installation Guide of Roll Crusher including

Roll Crusher

2024年12月3日 Roll Crusher Roll crusher features dual screening and crushing functionalities, enabling independent completion of both operations This simplifies the process system and Roll fitting is through tapered casted hub ring Heavyduty bearing pedestal with ease of operation The Maxwell Smooth Double Roller Crusher has very easy and accurate CSS setting through Square threaded Jack without insertion of Sims Smooth Double Roll Crusher Maxwell CrushtechSimple and Robust Structure: Ensures reliable operation and easy maintenance LowSpeed Operation: Reduces wear on crushing teeth, minimizes noise, and prolongs service life Efficient Single Roll Crusher for Sinter Crushing2024年10月8日 Roll crusher (doubleroll crusher) is suitable for coarse and intermediate crushing of brittle block materials in cement, chemical, electric power, mining metallurgy Roller CrusherCrushing EquipmentHongji Mine Machinery

Elecon Single Double Roll Crushers for Superior Crushing

Elecon offers a range of highperformance Single and Double Roll Crushers designed for efficient primary and secondary crushing of various materials in the mining, construction, and recycling FLS Double Roll Crushers are capable of impressively high throughput rates – up to 14,000 tph – thanks to the customised tooth and liner design and optimised installed power and drive setup, while our Eccentric Roll Crushers offers up to Roll crushers – ERC and double roll crusher – FLS 2023年6月22日 Fundamentals of roll crusher grinding In a roll crusher, material is fed from the top into a narrow gap (called the nip) between rotating cylindrical rolls, which grind the material to the desired particle size Roll crushers can be Hammermill and roll crusher maintenance and 2022年11月21日 3 Roll Fine particles fed into the crusher are screened out by the integrated static grizzly and bypassed through the crusher housing (a) The coarse feed material fraction is continuously crushed between the oscillating roll and the jaw until the product exits the crushing chamber at the bottom (b) The hydraulic gap setting/ retractionEccentric Roll Crusher

Easy Installation Automatic Electric Mild Steel

Ajanta Industries Offering low price Easy Installation Automatic Electric Mild Steel Double Roll Crusher in SHAPAR (GONDAL ROAD), Rajkot with product details company information2015年10月18日 *The roll crusher has a simple structure, compact, lightweight, reliable, low cost and easy maintenance * they give a very fine product size distribution and they produce very little dust *Coal is probably the largest user of roll crushers * The main disadvantage of roll crusher is low processing capacity *High wear, grinding teeth Roll crusherppt SlideShareThis study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product (a) Structure diagram and (b) functional principle diagram of cone crusherControl principle of roll gap The mechanical structure of roller crusher is presented in Figure 1 And the working principle can be summarized as following And the working principle can be Mechanical structure of roller crusher Download

.jpg)

Roll Crusher HRC HAZEMAG

The drive is assembled on a base frame, which is connected with the roll crusher The floating roll drive, also supported in pivoting mode, is connected with the floating roll rocker arm by a coupling rod This ensures that a constant drive belt tension exists during the retraction movement of the floating roll, and during gap adjustment2023年10月8日 Double toothed roll crusher less overcrushing rate, simple structure, easy to operate and maintain, more costeffective than other crushers Disadvantages: Not ideal for high moisture coal (exceeding 10%), Advantages: Shorter installation time, lower transportation costs, environmentally friendly6 Types of Coal Crusher: Which Is Best for Crushing My Coal?2024年7月25日 Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleDesign, Fabrication and Testing of a Double Roll CrusherTo provide optimum protection for the roll crusher, a hydraulic floating roll retraction system has been developed based on the successful system used in HAZEMAG impact crushers According to the product required, the roll is retained hydraulically in position with a precise and constant gap setting, thereby guaranteeing a product of uniform Roll Crushers HAZEMAG

.jpg)

20 DIY Can Crusher Ideas That Are Cheap And

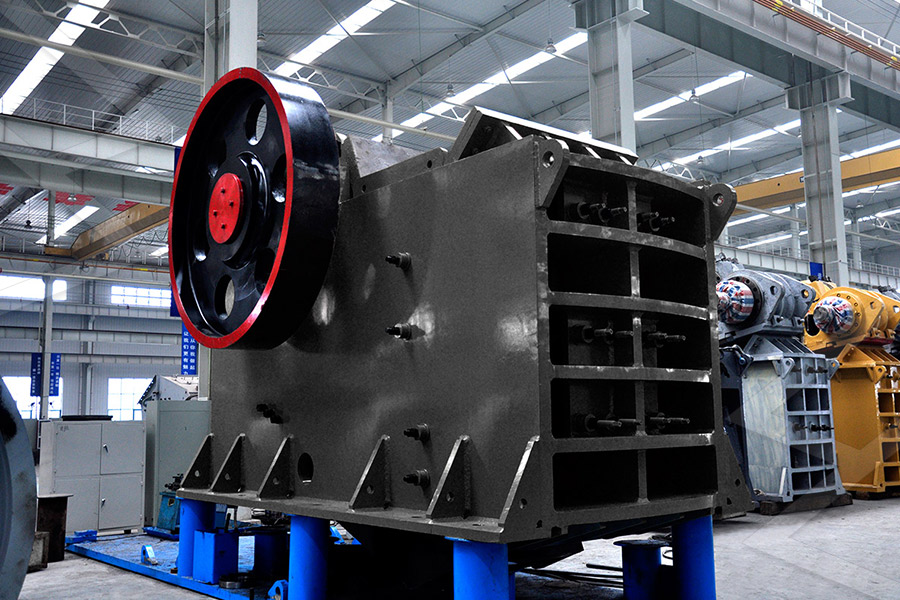

2024年9月21日 This can crusher makes it easy to get those cans smashed into a smaller size so they fit in your trash bin It's made from pallet wood, is superefficient, and can crush two cans at once Simple and easygoing 2019年9月11日 Its installation height is between 20% and 55% lower than similarperforming gyrator or jaw crusher options, in an overall lighter package The symmetrical arrangement of the eccentrically moved crushing roll allows for easy balancing, so foundation forces and vibrations are reduced to a minimum thereby opening up numerous new Thyssenkrupp Eccentric Roll Crusher AggNetRC type is a jaw crusher made by simple structure and that crushes chunks with economical, productive, and easy maintenance that meets today’s needs 2shaft Power roll crusher PRC1200P / PRC1500P / PRC1800P Overview Simple design which consist of both the world’s smallest installation height and durability Easy monitoring on Crusher Nakayama Iron Works6 天之前 Application: Mainly used for medium crushing and fine crushing of medium hardness stones (compressive strength below 100MPa) such as coal and limestone Roll crusher is not used in road gravel processing Advantages: simple, compact structure, low investment, convenient adjustment, and can be used to crush viscous materials7 Types of Stone Crusher and How to Choose the Best?

Industrial Crushers Double Roll Crusher Manufacturer from

Roll Crusher: Star trace roll crusher can be referred to as compressiontype roll crusher in the mining industry, they are used to crush mines of medium or low hardness, rocks that have low or medium rigidity during mine selection, for cement, chemicals, and industrial production of building materials, among others roll crushers have the 2015年4月24日 4 ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inchRoll crushers PPT SlideShareStone crusher commonly used models are PE series coarse jaw crusher, PEX series fine jaw crusher, impact crusher, cone crusher, impact crusher, roll crusher, and so on High crushing efficiency, with fine crushing, coarse grinding function Simple structure, easy installation, and maintenance, low operation costStone Crushers Machine Top 10 Manufacturer In China2023年11月15日 The IKN Roll Crusher can be installed at the cooler discharge Electrical Roll Crusher simple and easy operation ikn + Rail mounted for easy maintenance + Hardfaced roll teeth for long service life IKN Roll Crusher 3D layout 01042020 V2 + Optional water cooling for midcooler operation Created Date: 4/17/2020 9:12:29 AM Electrical Roll Crusher simple and easy operation

Care and Installation Guide Hay Conditioning Rollers

2024年12月5日 INSTALLATION AND CARE INSTRUCTIONS THE CRUSHER ® HAY CONDITIONING ROLLERS Some makes and models have stops, shims or limiting brackets of some kind We recommend they be removed See your machine’s make and model owner’s Manual The Crusher ® Rolls ARE DESIGNED TO TOUCH EACH OTHER Rollers should run 2019年1月10日 The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, and finished product material nature When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder Crusher and Its Types PDF SlideShare2003年3月18日 Double Roller Coal Crusher/Double Roll Crusher: 150TPH capacity 010mm adjustable discharge size I Double Roller Coal Crusher/Double Roll Crusher Usage: It is widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so onHigh Quality 2pg400*250 Double Roller Crusher2018年12月26日 For example, a singleroll crusher, employ shear together with impact and compression Shear crushing is normally used under following conditions When material is somewhat friable and has relatively low silica content For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger Construction, Working and Maintenance of Practical

.jpg)

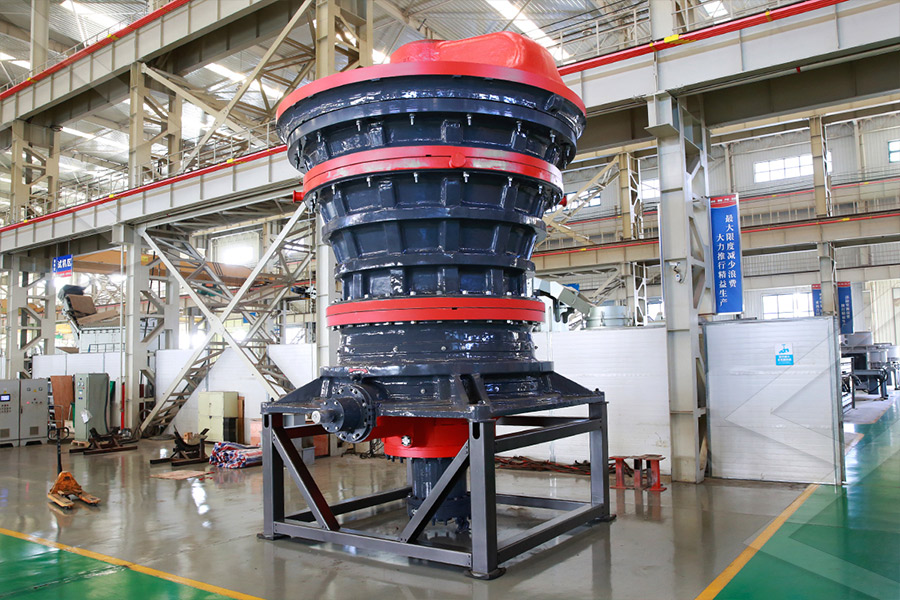

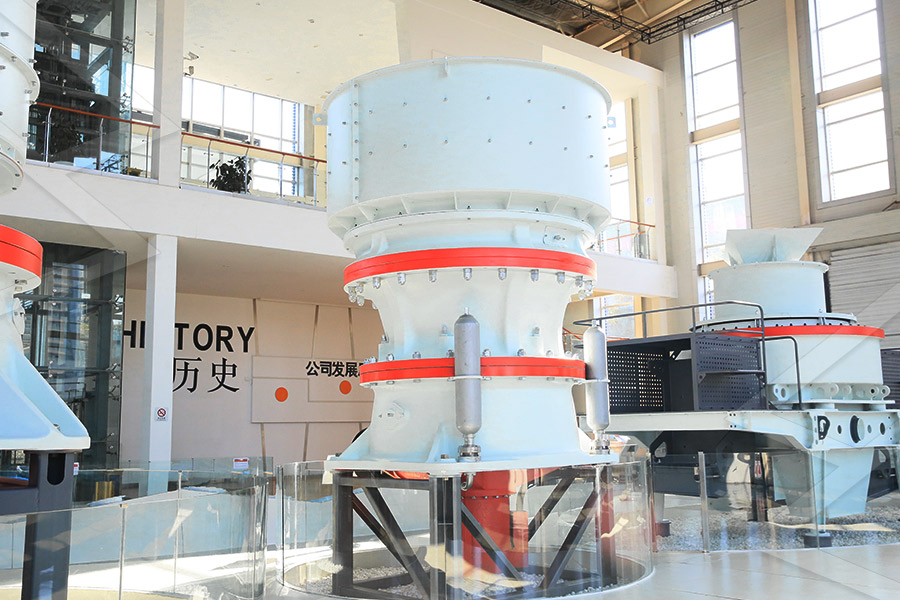

New insights into double roll crushing ScienceDirect

2023年11月1日 The core of the test plant is a double roll crusher DRC 450x450 toothed rolls Fig 3 shows a 3D view of the crusher without the drive units and inlet hopper The roll crusher has two cylindrical rolls, which are designed as fixed (2) and retractable (4) The retractable roll is pretensioned with two hydraulic cylinders (3), which press it 2017年10月4日 With the development of a completely new type of crusher, the ERC2525 eccentric roll crusher, thyssenkrupp said it has achieved a quantum leap in primary crushing The new crusher features a particularly flat and robust design and high throughputs of up to 3,000 tons per hour (t/h), enabling it to process hard rock and ores efficiently and thyssenkrupp Develops New Eccentric Roll Crusher E MJ2024年10月10日 The roller crusher, also known as a double roller crusher, is a kind of mining machinery mainly used for crushing oresIt has the advantages of small size, large crushing ratio (58), low noise, simple structure, easy maintenance, etc The particle size of the crushed material is uniform, the overcrushing rate is low, maintenance is convenient, and overload protection is Roller Crusher: From Functionality to Maintenance JXSC 2022年7月7日 Double roll crusher with a pair of opposite rotating rolls round, multiroller crusher, two pair or several pairs of opposite rotation of the round roll Single roller crusher roller length is generally less than the diameter for the primary crushing Easy to install and only need simple foundation; Can adjust the pressure and size easily Double Roller Crushers SolidsWiki

.jpg)

Roll Crushers: Principles, Applications, and Benefits in

2017年3月10日 A few years ago we had a mill consisting of a 10 by 20 roll crusher, two 6 by 20 breakers in parallel, and a pair of 20 by 28 Krom rolls and screen near the end of the operation, thus making the screeninstallation as simple as possible In oremilling, the use of rolls is desirable when it is necessary to keep the slimes down to the 2023年6月22日 Fundamentals of roll crusher grinding In a roll crusher, material is fed from the top into a narrow gap (called the nip) between rotating cylindrical rolls, which grind the material to the desired particle size Roll crushers can be Hammermill and roll crusher maintenance and 2022年11月21日 3 Roll Fine particles fed into the crusher are screened out by the integrated static grizzly and bypassed through the crusher housing (a) The coarse feed material fraction is continuously crushed between the oscillating roll and the jaw until the product exits the crushing chamber at the bottom (b) The hydraulic gap setting/ retractionEccentric Roll CrusherAjanta Industries Offering low price Easy Installation Automatic Electric Mild Steel Double Roll Crusher in SHAPAR (GONDAL ROAD), Rajkot with product details company informationEasy Installation Automatic Electric Mild Steel

Roll crusherppt SlideShare

2015年10月18日 *The roll crusher has a simple structure, compact, lightweight, reliable, low cost and easy maintenance * they give a very fine product size distribution and they produce very little dust *Coal is probably the largest user of roll crushers * The main disadvantage of roll crusher is low processing capacity *High wear, grinding teeth This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product (a) Structure diagram and (b) functional principle diagram of cone crusherControl principle of roll gap The mechanical structure of roller crusher is presented in Figure 1 And the working principle can be summarized as following And the working principle can be Mechanical structure of roller crusher DownloadThe drive is assembled on a base frame, which is connected with the roll crusher The floating roll drive, also supported in pivoting mode, is connected with the floating roll rocker arm by a coupling rod This ensures that a constant drive belt tension exists during the retraction movement of the floating roll, and during gap adjustmentRoll Crusher HRC HAZEMAG

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 Double toothed roll crusher less overcrushing rate, simple structure, easy to operate and maintain, more costeffective than other crushers Disadvantages: Not ideal for high moisture coal (exceeding 10%), Advantages: Shorter installation time, lower transportation costs, environmentally friendly