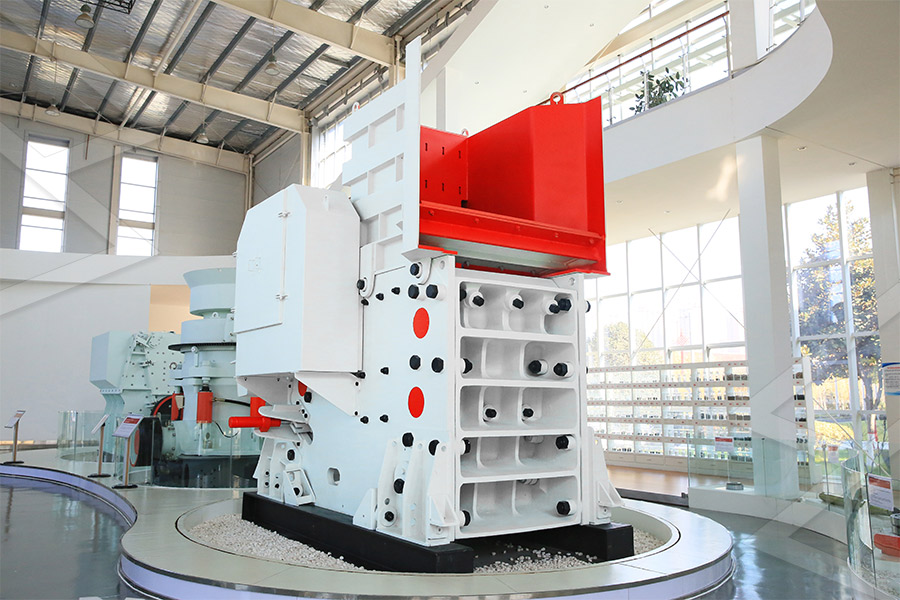

Small Gyratory Crushing Equment

.jpg)

Simulation and optimization of gyratory crusher

2020年10月1日 To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this paper First, the 2024年10月1日 In this research, a multibody dynamic (MBD) model of a gyratory crusher was built for motion simulation, and the discrete element method (DEM) was applied to describe Analysis and optimization of vibration characteristics of gyratory 2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power(PDF) Torque Analysis of a Gyratory Crusher with 2021年5月1日 To optimize the crushing chamber of the gyratory crusher, the discrete element method (DEM) is used to explore the influence of the concave curve height, concave curve Simulation and optimization of crushing chamber of gyratory crusher

.jpg)

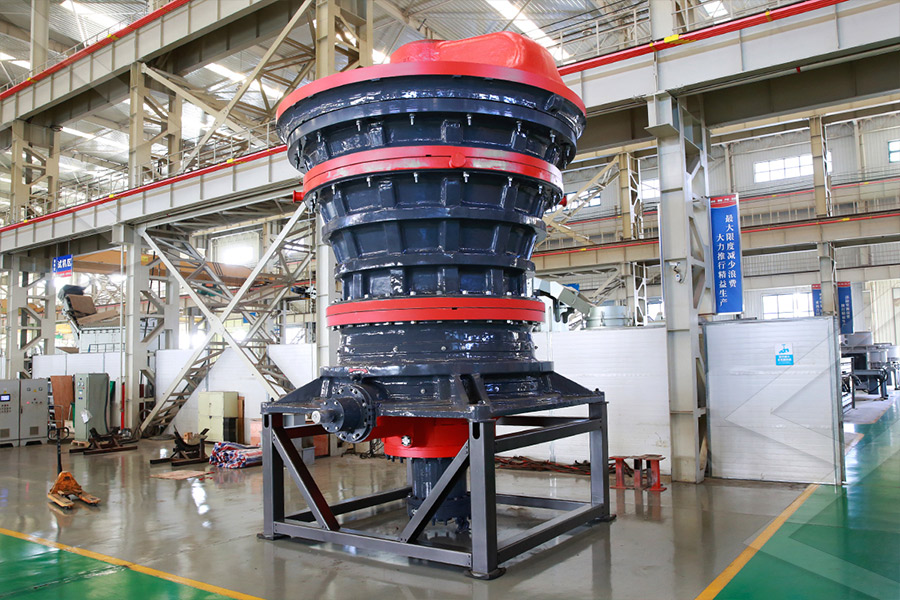

Industrial Solutions Gyratory crushers ThyssenKrupp

2022年11月21日 With crushing chambers of varying designs, these machines have either a high crushing ratio for preparing raw materials for secondary crushing or a low crushing ratio for 2024年5月30日 The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely Crushing Systems flsmidthcement2024年1月1日 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for Gyratory Crusher SpringerLinkGyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by: Its gape and Gyratory Crusher (Gyratory Crushers Explained)

Advanced gyratory crushers – FLS

FLS gyratory crushers offer robust performance with advanced technology for more productive, more efficient primary and secondary crushing With innovative features for ease of 2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power(PDF) Torque Analysis of a Gyratory Crusher with 2021年5月1日 Compared with the gyratory crusher, this type of crusher has a relatively small crushing force and compression ratio, and their changes are small Therefore, the impact of the crushing chamber shape on productivity is relatively small, the production performance can be improved by increasing the mantle shaft speed, and the cavity has a Simulation and optimization of crushing chamber of gyratory crusher 2016年2月17日 The use of large primary crushers made secondary crushing necessary, but this department was taken care of nicely by the existing lines of standard gyratory machines In commercial crushed stone plants, there was gradual increase in the number of products, but generally a sufficient demand existed for the coarser grades for ballast and macadam roads to Secondary Gyratory Crushers 911Metallurgist

.jpg)

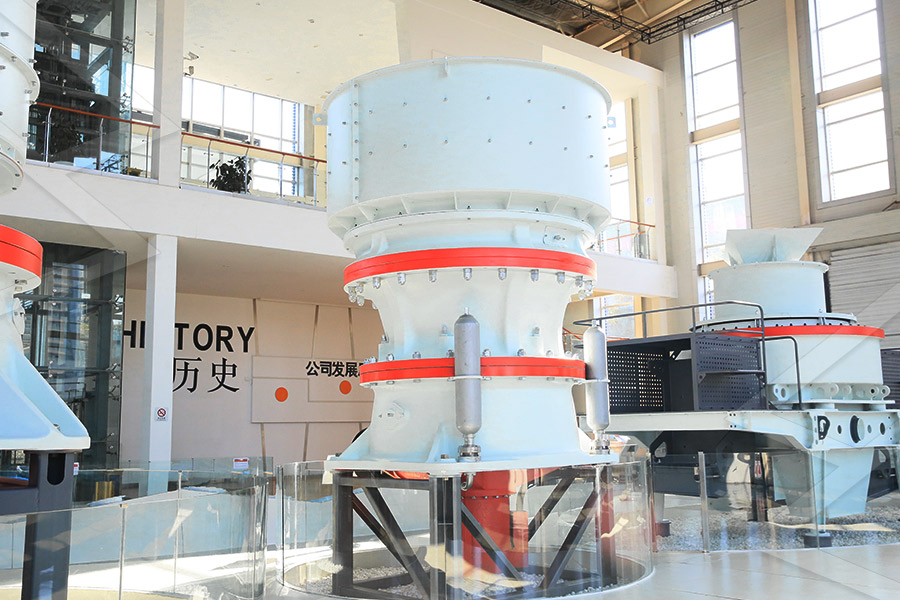

FLS Empowering the future of mining FLSmidth

FLS is a leading, full flowsheet minerals processing supplier to the global mining industry We deliver proven technologies and services across the lifecycle of operations, and have set targets of providing solutions for zeroemissions mining by 2030 with our MissionZero programme2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic Gyratory Crushers SolidsWiki2021年11月4日 Unique crushing chamber provides large capacity and large crushing ratio Large opening permits max 350mm stone feed More 40mm minus product can be obtained than conventional Gyratory CrusherDH Gyratory Crusher Crushing/Grinding EARTHTECHNICA 2004年11月1日 The dynamic nature of the crushing process is fundamental to a desired flow of material from mine to mill Though fragmentation and comminution occurs during the blasting, crushing and milling steps of the process, there is a better opportunity, with regards to costs, to optimize the first two processes since the cost increases as the ore goes from blasting to Improved gyratory crushing operation by the assessment of

.jpg)

Gyratory Crushers SolidsWiki

2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC MineCreate fine powders for industrial projects with crusher machines Browse the gyratory crushing equipment range on Alibaba for all types at wholesale pricesGyratory crushing equipment2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various Gyratory Crushers SolidsWiki

.jpg)

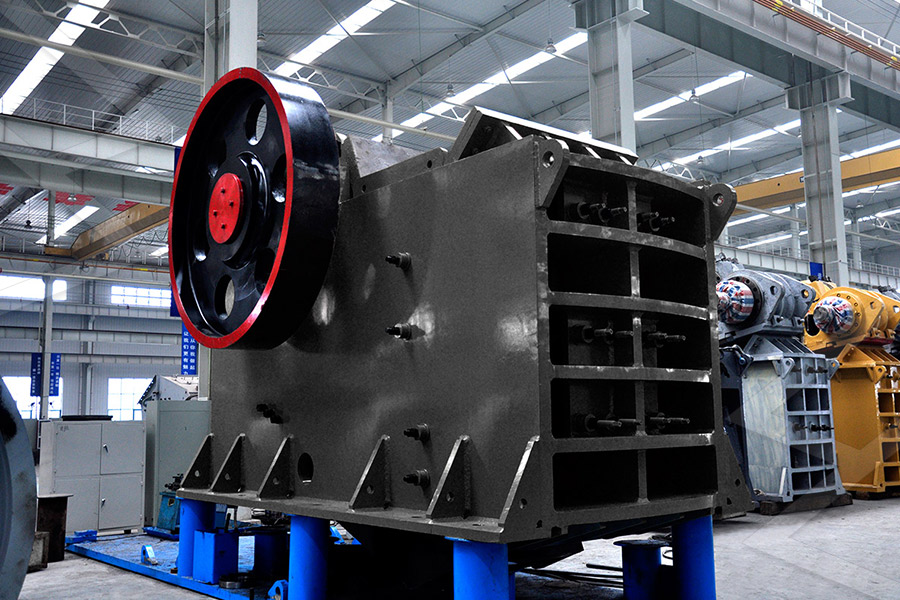

2 GYRATORY CRUSHERS 911 Metallurgist

2017年4月19日 The gyratory crusher, whether used as a primary or secondary is essentially a gravitytype machine Material flows vertically from top to bottom It receives a large coarse feed, usually runofmine, and its product normally requires additional crushing before produc ing the final product The gyratory crusher is a pressure crushing2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic Gyratory Crushers SolidsWikiContribute to lbsid/en development by creating an account on GitHuben/169/sand grinding ball mill small size secondhand gyratory 2023年11月1日 As coarse crushing equipment, the gyratory crusher is widely used in industries such as mining, metallurgy, and building materials [1], 12 (a), it can be observed that the fracture surface exhibits a rocklike pattern with polyhedralshaped grains, and small cracks can be observed in the red circle region SEM analysis of sample B Failure analysis of eccentric bushings in large gyratory crusher

DEM simulation and optimization of crushing chamber shape of gyratory

2024年4月1日 The geometry of the crushing chamber is one of the essential factors that influence the performance of the gyratory crusher (Dong et al, 2009, Dong et al, 2009); it refers to the shape of the contact with the ore between the mantle and the concave during the operation of the gyratory crusherThe geometric features of the mantle and concave include both linear 2024年3月15日 A gyratory crusher consists of a conical crushing head that gyrates inside a funnelshaped casing Material is crushed in the Vshaped space between the crushing head and casing as the head gyrates The bottom of the crushing head moves in an eccentric pattern towards and away from the stationary casing wall, repeatedly crushing the material until it is Gyratory Crusher g2 PDF ScribdGyratory Crushers are used for crushing ore in miningGyratory crushers are designed to handle large rocks and ores with high hardness and toughness Proper design of both gyratory crusher mantle and concave liners leads to lower and more consistent crushed product size, better throughput, highly predictable liner changeout intervals and overall better asset utilisationGyratory Crushers Crushing Equipment Ore Processing2023年12月13日 Type: Gyratory Crusher Motor Type: AC Motor Motor Power: 630 Application: Mine Materials: RockOre Outlet Size: 150300mmGyratory Crusher China Gyratory Crusher and Hydraulic Gyratory

43 ConeGyrotary Crushing Screenings for sale in Australia

43 ConeGyrotary Crushing Screenings for sale in Australia Save my search Sort by: Featured Featured Price (High to Low) Price (Low to High) Year Made (High to Low) Year Made (Low to High) Make (AZ) Make (ZA) Last Updated Most Recent 2024年4月1日 The ore particles are filled into the crushing chamber when the gyratory crusher is in operation, as the mantle rotates eccentrically around the gyration point, the ore particles are continuously squeezed to accomplish fragmentation At present, the studies of crushing chamber shape are relatively small and most of the studies have been DEM simulation and optimization of crushing chamber shape of gyratory 2021年5月1日 Compared with the gyratory crusher, this type of crusher has a relatively small crushing force and compression ratio, and their changes are small Therefore, the impact of the crushing chamber shape on productivity is relatively small, the production performance can be improved by increasing the mantle shaft speed, and the cavity has a Simulation and optimization of crushing chamber of gyratory dynamic load calculation of crusherThe primary rock breaker most commonly used in large plants is the gyratory crusher,of which a typical section is shown in Fig5It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)Rock Crushers Mineral Processing MetallurgyThe disadvantage of the known jaw rock en/169/gyratory crusher dynamic loadsmd at main

How do a gyratory crusher work? amcrushers

The material travels downward between the two surfaces being progressively crushed until it is small enough to fall out through the gap between the two surfaces A gyratory crusher is used both for primary or secondary crushing >Next: Oman 300TPH Limestone Crushing Plant2004年11月1日 To optimize the crushing chamber of the gyratory crusher, the discrete element method (DEM) is used to explore the influence of the concave curve height, concave curve radius, eccentric angle, and Improved gyratory crushing operation by the assessment of The fragmentation operation was done via a small long shaft laboratory gyratory device having size range 635711 mm, set range 254445 mm, rotational speed (rev/min) at 700 and finally power Showing the pictorial image of the laboratory gyratory 2016年2月28日 The gyratory should never be used for materials containing more than a small percentage of such contamination, the allowable amount being that which the clean crushed rock will keep scoured off of the diaphragm Flushing the diaphragm will prevent packing of this dirty material, but this practice is usually not permissible in the crushing plantGyratory VS Jaw Crushers: Advantages Disadvantages

HighSpeed Gyratory Crushing –> Fine Cone Crushers

2015年11月22日 I covered briefly the development of various types of reduction crushers of the gyratory family Below you see a gyratory reduction crusher, which introduced the cylindrical top shell, flared head, and reversible concavesEven with the older style of straight concaves, with which this machine was originally fitted, it represented a distinct step forward in secondary 2011年6月21日 The same approach was used for investigating the influence of liner wear on crushing performance for a primary gyratory crusher [71] Fig 6 shows an example of flow and breakage prediction in a (PDF) THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING 2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power(PDF) Torque Analysis of a Gyratory Crusher with 2021年5月1日 Compared with the gyratory crusher, this type of crusher has a relatively small crushing force and compression ratio, and their changes are small Therefore, the impact of the crushing chamber shape on productivity is relatively small, the production performance can be improved by increasing the mantle shaft speed, and the cavity has a Simulation and optimization of crushing chamber of gyratory crusher

制粉-10.25公众号.jpg)

Secondary Gyratory Crushers 911Metallurgist

2016年2月17日 The use of large primary crushers made secondary crushing necessary, but this department was taken care of nicely by the existing lines of standard gyratory machines In commercial crushed stone plants, there was gradual increase in the number of products, but generally a sufficient demand existed for the coarser grades for ballast and macadam roads to FLS is a leading, full flowsheet minerals processing supplier to the global mining industry We deliver proven technologies and services across the lifecycle of operations, and have set targets of providing solutions for zeroemissions mining by 2030 with our MissionZero programmeFLS Empowering the future of mining FLSmidth2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic Gyratory Crushers SolidsWiki2021年11月4日 Unique crushing chamber provides large capacity and large crushing ratio Large opening permits max 350mm stone feed More 40mm minus product can be obtained than conventional Gyratory CrusherDH Gyratory Crusher Crushing/Grinding EARTHTECHNICA

.jpg)

Improved gyratory crushing operation by the assessment of

2004年11月1日 The dynamic nature of the crushing process is fundamental to a desired flow of material from mine to mill Though fragmentation and comminution occurs during the blasting, crushing and milling steps of the process, there is a better opportunity, with regards to costs, to optimize the first two processes since the cost increases as the ore goes from blasting to 2022年7月7日 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic Gyratory Crushers SolidsWikiGyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC MineCreate fine powders for industrial projects with crusher machines Browse the gyratory crushing equipment range on Alibaba for all types at wholesale pricesGyratory crushing equipment